Transformative Journey From Pixels to Physical Forms in 3D Printing – Technologist

Every day, we amazingly think about the speed at which technology continues to transform our lives. Among the trailblazers in this digital revolution is the fascinating world of 3D printing. Not long ago, creating a custom object involved an intricate dance of manufacturing units, supply chain hurdles and significant costs.

Now, with the simple click of a mouse, to understand more about SLS printing, online platforms bring this technology to our fingertips. But to delve into its core–a process that’s redefining production and expanding the realms of possibility for designers and creators across the globe.

The Magic of Turning Designs into Reality with 3D Printing

Imagine turning a thought, perhaps a unique piece of jewelry or a replacement part for a gadget into a physical object you can hold. This is the everyday magic of 3D printing. It starts with a digital design, an artistic creation made on a computer.

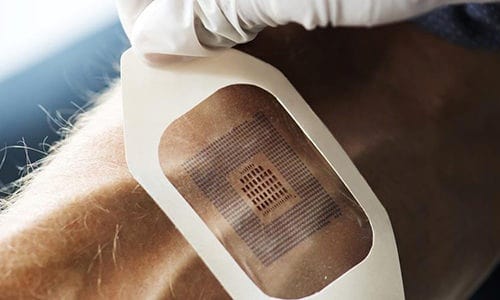

Once complete, this design is transformed by a printer that meticulously adds layer upon layer of material until the final object takes shape. The real-life applications are endless, ranging from fashion accessories to life-saving medical implants, showcasing the flexibility and adaptability of this technology.

The convergence of creativity and technology finds one of its most potent expressions in 3D printing. Artists can sketch out their wildest visions, engineers can draft complex schematics, and together, these ideas coalesce into tangible objects through this technology.

Even in education, teachers now impress upon young minds the practical applications of geometry and design as they watch their drawings rise from sheets of paper to the satisfying heft of three dimensions. The progression from pixels to a physical form is not just a manufacturing evolution; it’s a conduit for creative problem-solving and innovation across numerous fields.

Understanding the Basics of SLS Printing and its Unique Benefits

SLS is the abbreviation for Selective Laser Sintering and this particular method in 3D printing is presented as robust and accurate. It studies the welding process by mixing the tiny particles of the polymer powder with the solid structure by a high-powered laser. On the contrary to other printing means of production SLS do not necessitate support structures that’s why you can easily create complicated and detailed designs without sacrificing clearance space or some fabrication difficulties.

This distinct advantage means it can create moving parts in one go, which would have been inconceivable with traditional manufacturing. The result is a durable and detailed creation, turning what once was impossible into something achievable.

The Role of Online Platforms in Simplifying the 3D Printing Process

Ideas can come to us from anywhere, and we can now easily realize them with the help of online 3D printing platforms. These services have made 3D printing more accessible to everyone with internet access, negating the need for expensive equipment or specialized skills for design and manufacturing.

You can upload a digital model, alter it to your specifications, and have the finished product delivered right to your door from the comfort of your living room. Numerous success stories have been made possible by these platforms, from kids completing their school projects to businesses developing new technologies.

From Artists to Inventors: Who is Utilizing 3D Printing and why?

Not only engineers and designers of products may benefit from the 3D printing boom. Numerous professionals, including educators, artists, and healthcare providers, have embraced technology due to its speed and versatility. Inventors iterate faster, doctors customize implants for patients, and artists create forms that defy traditional methods.

One interesting tale is a ceramicist who molds intricate forms using 3D printing, which she then uses as the foundation for her sculptures. These kinds of tales demonstrate how technology fosters innovation and advances useful solutions.

How Sustainable Practices Intersect with Modern 3D Printing Techniques

Today’s industrial methods must take sustainability into account, and 3D printing is rising to the occasion. Because the technology adds material only where needed, as opposed to traditional technologies that cut away at larger blocks, it naturally generates less waste.

These days, a lot of 3D printers use eco-friendly materials like recycled metal and biodegradable plastic. Initiatives even exist to turn plastic waste from the ocean into filaments for 3D printers. These projects highlight the creative applications of 3D printing while also advancing a more ethical and sustainable method of manufacturing goods.

The Economic Impact of Bringing Customized Products to Market Faster

One of the most markable changes in the economic field resulting from 3D printing’s ability is to manufacture customized products in a small span and at much-reduced labors and time costs. Prototyping that involves building of physical models at high cost and time is no more required because a model of the design may be printed quickly.

The speeding up of verifying, enhancing, and making available products to customers is made possible by this acceleration and such a time-bound probably was not possible before. This procedure, believed with competition and innovation, may bring to order, diverting whole industries’ way. The 3D printing places the balance of power in terms of competing between established enterprises and small businesses on a fair ground.

Demystifying 3D Printing: An Overview for Non-technical Enthusiasts

Do not be scared if technology has surpassed your wonders but has frightened you as well. The so-called “3D printing” is no modern phenomenon that only scientists and engineers can access. Basically, it means a machine that can be as much as an ordinary office paper printer used by applying the commanders to the design can breathe a life into it.

Once a reporting beginner is an excess of materials, e.g. easy-to-use software and a step-by-step guides, kindliness to them. 3D printing can be used for phone cases, personalized home numbers, kitchen appliances, and more. In general, all you need to do is to simply design them using 3D software and print them through a 3D printer of your choice.

Looking into the Future: Predicting the Evolution of 3D Printing Technology

There are no indications that the momentum of 3D printing will slow down. Trends toward printers that can handle numerous materials at once, as well as materials that are increasingly more robust and diverse, are already evident. Future developments could possibly combine several technologies—such as electronics printing into a single item.

Furthermore, the day when owning a 3D printer at home is as common as owning a microwave is not too far off, given the rate at which printer prices are declining. With the only limit being our ingenuity, 3D printing will undoubtedly have a greater and wider impact on all facets of our lives, from the items we use to the way we approach production and problem-solving.